Argentium Sterling Silver, What It Is, Why We Use It And Why You Will Love It

(Updated on 10/28/21)

In the beginning.....there was sterling silver, plain ole sterling, one of the metals many of us got our start on, not only because of it's price point for the beginning metalsmith; silver is a perfect material to work with, which is why humanity has used it for jewelry and utility items such as vessels for millennia. Over the years we gradually replaced the old standard .925 with .935 Argentium sterling in our designs. The reason, it's properties. Argentium is higher in pure silver content, .935 (93.5%) over regular sterling .925 (92.5%), which makes it superior in many ways. It's not just the slightly richer nature of Argentium that gives it its edge over traditional sterling though, there's a magic ingredient as well.......Germanium. The element Germanium is the key to so many of the awesome properties of Argentium sterling silver. This metalloid element, somewhere between a metal and non-metal, is added to the alloy in just a few percent, and voila!

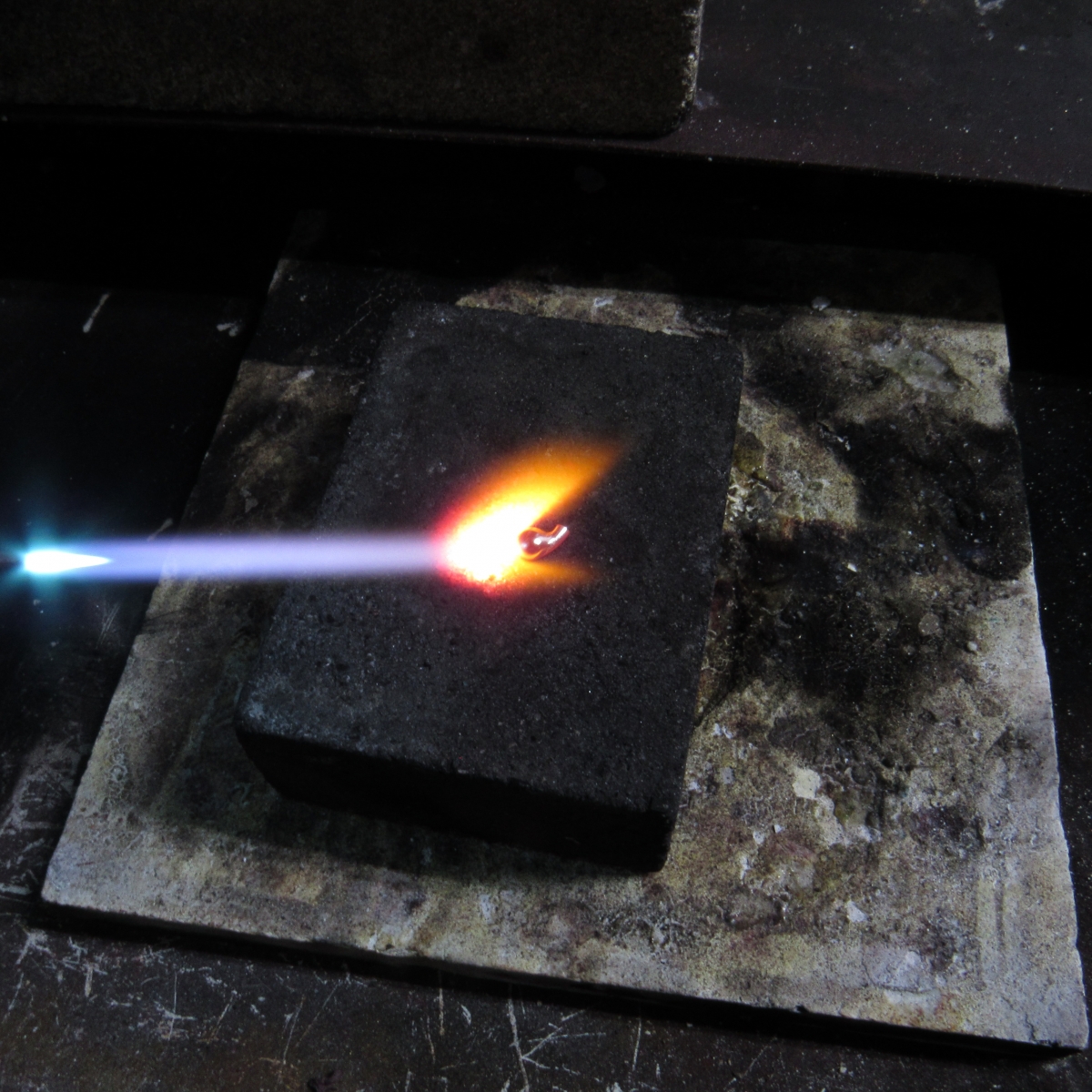

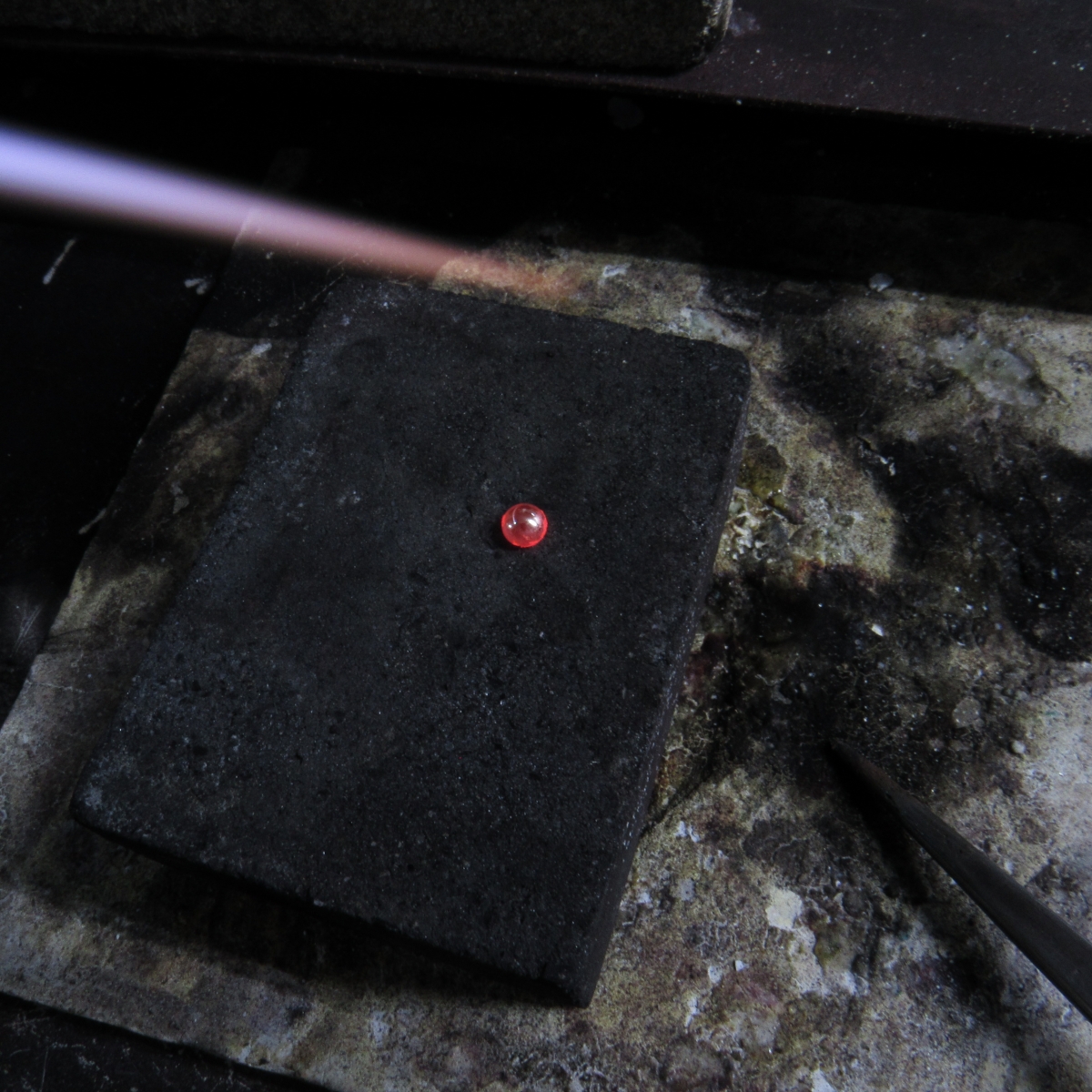

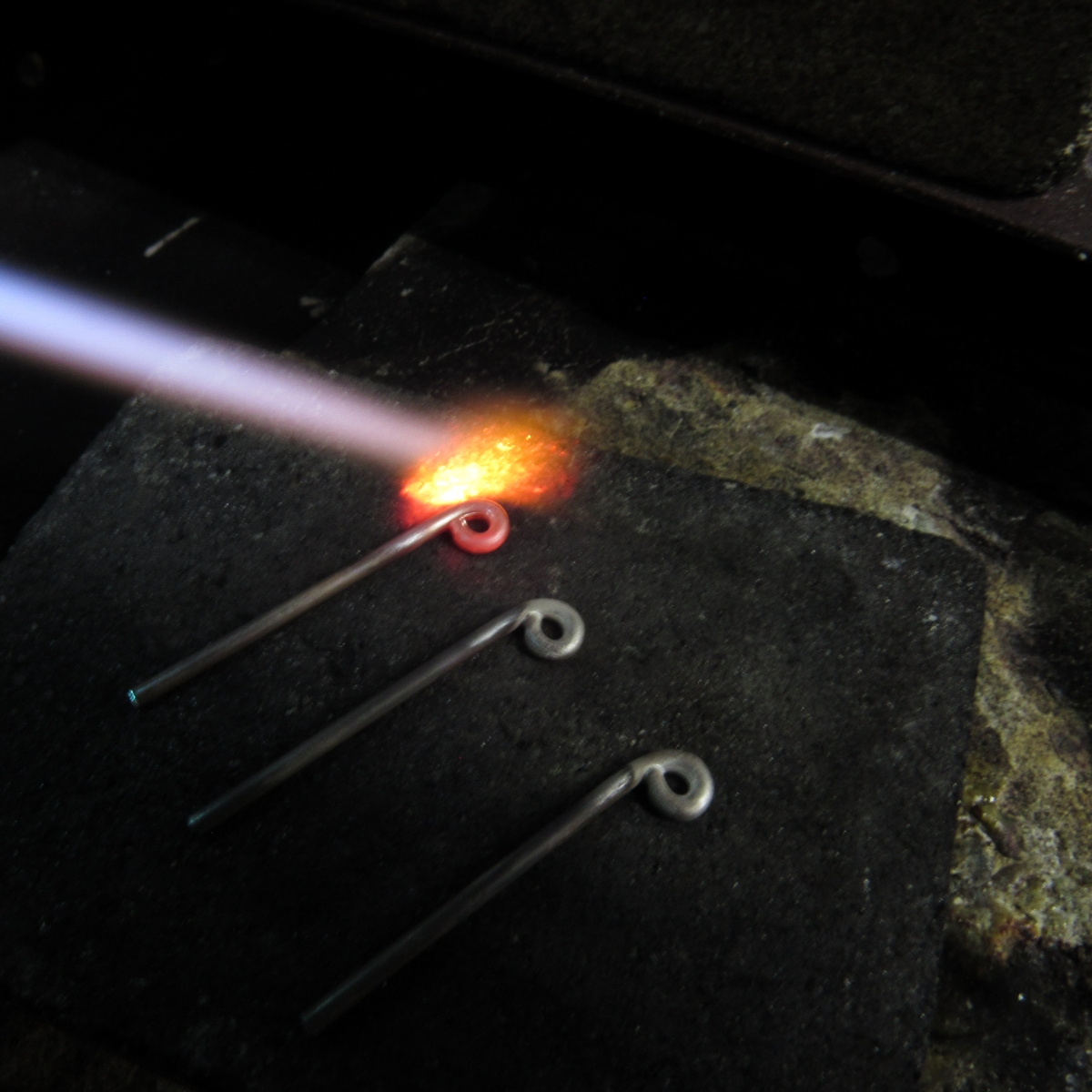

For the metalsmith, Argentium provides a great deal of forgiveness and flexibility that traditional sterling does not have. In high temperature joining processes, like soldering and fusing, Argentium resists oxidation and expansion allowing it to behave in a totally new way. Firestain, which is very common and pesky when soldering and fusing sterling, is much reduced with Argentium, although not eliminated. These antioxidative properties can help to cut down on intensive finishing processes and times.

It is also eco-friendly, as it is made using recycled silver content. With its superior properties, being stronger and more oxidation resistant less intensive manufacturing processes and upkeep on the final product reduce its environmental impact. Customers appreciate the strength and tarnish resistance of Argentium, knowing that their jewelry is made with a superior material for pieces that will stand the test of time. Although it costs a little more, the results are worth it.

Unfortunately, many people are not aware of Argentium, and there are those that are a little hesitant to purchase Argentium jewelry, the reason.... people just aren't familiar with this newer alloy. This is why we decided to write this little primmer regarding our usage of Argentium and why it's such a wonderful alloy for the maker and why buyers will prefer jewelry made from AGS. For in depth information a great resource can be found here:

https://www.argentiumsilver.com/

Below are two links to examples our our Argentium Sterling work.

Argentium Silver Moonstone Crescent Moon Necklace

Egyptian Inspired Argentium Silver Dangle Earrings

Images from Left to Right: AGS ball being formed, cooling, AGS ball compared to plain sterling on the right (clear difference in surface shrinkage and oxidation!), fusing AGS components (no solder required).

Comments

Love it

I love it!

Post new comment